|

|

|

|

|

|

|

|

|

|

|

|

Exterior Cavity Walls Applications

Spray Polyurethane Foam on Exterior Walls

The objective of this case study is to discuss an insulation technique that works particularly well on buildings designed with a brick veneer as the finished surface of the exterior walls. The actual exterior wall can be constructed with concrete block or a combination of metal studs and one of several exterior sheathing materials.

|

|

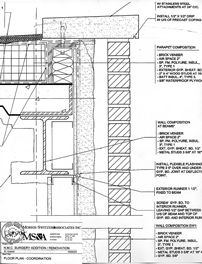

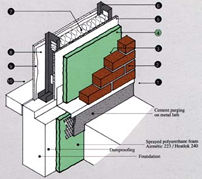

| This diagram from Demilec illustrates a typical masonry wall assembly using foam as an exterior insulation behind a brick veneer wall. | |

|

|

| This is an example of foam being used as the exterior insulation. Three inches of foam is shown in this example; this is thick enough to be a vapor retarder as well. |

The significant aspects of this technique are two-fold. 1.) Install insulation on the outside of the building rather then the inside. 2.) Use spray polyurethane foam as the insulation rather then other materials on the market like rigid foam boards. Brick ties are attached to the exterior sheathing, the exterior insulation is applied and the brick veneer is added, leaving an air space between the brick veneer and the insulation for drainage.

Insulating the outside of a building has many advantages:

-

Applying insulation from the outside avoids the problem of thermal bridging.

|

|

|

|

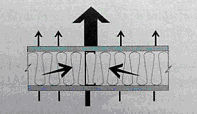

This diagram illustrates the concept of thermal bridging. |

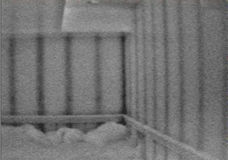

Infrared image portrays the wall studs acting as a thermal bridge. |

-

Insulating the exterior allows for a continuous air barrier and vapor retarder. There are fewer details and obstructions compromising the effectiveness of the vapor barrier.

|

|

|

|

|

Photographs showing typical steel building construction and the many projections, details, and penetrations that would make installing insulation and a vapor retarder on the inside very difficult. |

||

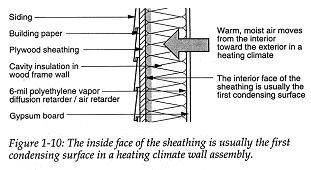

Because the insulation is on the outside and there is no cold surface on the backside of the exterior sheathing, condensation inside the wall cavities is avoided.

|

|

|

|

This diagram from Moisture Control Handbook by Joe Lstiburek and John Carmody illustrates how condensation can form in wall cavities in a heating climate. |

Once the decision has been made to insulate on the exterior, designers must choose from several insulation products and techniques. The major products are:

-

Rigid foam board

-

Rigid fiber board

-

Spray Polyurethane foam

Following is an evaluation of these materials which considers the important performance criteria.

-

Continuous thermal barrier.

-

No seams or holes to seal, especially around brick ties.

-

Complete adherence to a wide variety of exterior sheathing.

-

Appropriate R-value with a low enough permeance rating to serve as an air barrier and vapor retarder that will meet or exceed building code requirements.

Rigid foam boards

Rigid foam boards are a good insulation material but, if installed improperly, the effectiveness of the material is compromised. With numerous seams, joints, and cuts necessary to fit the foam sheets together, the possibility of leaving a void in the thermal envelope is significant.

|

|

|

|

Improperly installed rigid foam boards leave gaps in the thermal barrier. |

Brick ties penetrate the rigid foam boards leaving holes that compromise the thermal envelope. |

Another major problem with foam boards as the insulation method for masonry buildings is the brick ties. Each brick tie causes a penetration in the thermal envelope. Often, the brick tie makes a larger hole than necessary in the rigid foam board. These holes, if left unsealed, compromise the thermal envelope.

While rigid foam board can serve as the air barrier if it is properly cut, fit, and the joints and penetrations sealed, it cannot serve as the vapor retarder.

Rigid fiber boards

|

Rigid fiber board is a mineral-wool insulation made from basalt and slag. Like rigid foam boards, the product is manufactured, shipped, and installed in sheet form. Installers of this product face the same installation issues as rigid foam boards present, such as the need for careful fitting and sealing of all penetrations. There is also the problem of sealing penetrations caused by brick ties.

Like rigid foam board, rigid fiber board can serve as the air barrier if properly cut, fit, and the joints and penetrations sealedIt can not serve as the vapor retarder.

Spray Polyurethane Foam

Spray polyurethane foam has the application flexibility and insulation properties that make it the best choice for exterior insulation applications.

-

Polyurethane foam applies well to many different sheathing materials.

|

|

|

|

|

Polyurethane foam applied to metal sheathing. |

Polyurethane foam applied over concrete block. |

Polyurethane foam applied to exterior gypsum sheathing. |

-

Spray foam forms a continuous thermal barrier around the building envelope.

-

There are no seams to seal which makes it less labor intensive.

-

Foam creates a tight seal around the brick ties, thus maintaining the integrity of the thermal envelope.

-

Polyurethane foam not only serves as the insulation, but can also be the air barrier and vapor barrier if applied at the correct thickness.

Related Information

-

See more examples of architectural details using foam as an exterior insulation.

-

Specifications for air barriers and air/vapor barriers (ABAA sample specification) and spray-applied foam.

-

Related masonry product information and specifications for exterior insulation applications.

-

Read Case Study, Bombardier Office Building, for more information and photographs of this exterior wall application project.

-

See the Building Envelope Theory section of Vapor Retarders for more information and the results of research done by the National Research Council of Canada.

-

Visit our Past Projects section of the site to view a list of other projects using exterior wall applications behind brick veneer.

-

Read our AIA/CES course description on Exterior Wall Applications.

- SUPERGREEN LAM™ (Liquid-applied Membrane)