|

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

|

|

The Use of Polyurethane Foam Technology in HistoricRenovation and Remediation WorkCase StudiesCurrier Gallery of Art

The Currier Gallery of Art 1995 Renovation – Architect: Anne Beha In the late

1800s, former Governor

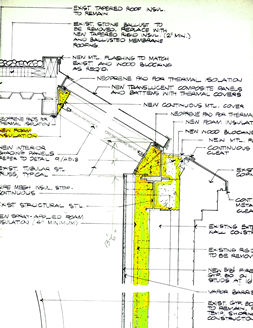

The roof in the original 1929 building is steel-framed with concrete infill below skylights which provide diffused natural light through ceiling lay-lights to the exhibit areas below. Polyurethane foam work for this project included insulating the underside of the low edge of the roof slab and the back of the box gutter built into the cornice. The goal was to reduce heat loss and prevent condensation which was dripping into the galleries below.

The majority of the gallery renovations involved the installation of new climate-control equipment in the galleries and the art storage spaces. The related building envelope work was designed to reduce equipment size and minimize energy consumption while avoiding the creation of moisture-related problems. The engineer specified 4" of spray-applied polyurethane foam (R=28, perm<.8) and foam sealants to repair and upgrade the exterior wall thermal envelopes in all of the climate-controlled spaces. Polyurethane foam was also used to isolate the pavilion galleries and the art storage areas from the rest of the building. The spray foam was applied directly onto block back-up walls to a thickness designed to prevent condensation on the inside and moisture migration into the masonry. Access to the wall surfaces in the West Pavilion and Fuller Gallery pavilion wings was gained by removing the interior display sheathing. Spray application was chosen over injection as the space behind the walls housed duct work and the size of the wall cavities made filling them impractical.

Foam sealant was used to seal and insulate the structural steel roof framing to prevent air leakage, condensation, and thermal bridging where possible. This work was coordinated with the replacement of the gallery skylights. The new underground art storage facilities beneath the new plaza (shown here under construction) and in the basements of the two 1965 pavilion addition wings were insulated with 3" of closed-cell polyurethane foam (R=21, perm <1). The undersides of the recessed first floor entry slabs were insulated with four inches of spray-applied foam (R=28, perm<.8).

Continue on to NH Historical Center | ||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

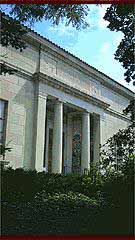

Moody Currier laid plans for a generous gift to the people of New Hampshire. His plan was realized when the doors of the Currier Gallery of Art were opened to the public in October 9, 1929. When the museum opened, the permanent collection consisted of only a few oil and watercolor paintings, and scenic wallpaper panels donated by early patrons. Because the permanent collection was so small, the first exhibitions were loaned to the Currier from sister museums. Over the course of seven decades the collection has grown significantly and the Currier is now considered one of the finest small museums in the country. In 1979, the Currier expanded its facilities by adding two pavilions to its 1929 building. The pavilions, designed by the architectural firm of Hardy Holzman Pfeiffer, increased the museum’s exhibition space by 60%. A second major renovation and addition project was undertaken in May of 1995 and lasted through the Spring of 1996. (Currier Gallery of Art

Web Site; Grand Opening Brochure, 1996)

Moody Currier laid plans for a generous gift to the people of New Hampshire. His plan was realized when the doors of the Currier Gallery of Art were opened to the public in October 9, 1929. When the museum opened, the permanent collection consisted of only a few oil and watercolor paintings, and scenic wallpaper panels donated by early patrons. Because the permanent collection was so small, the first exhibitions were loaned to the Currier from sister museums. Over the course of seven decades the collection has grown significantly and the Currier is now considered one of the finest small museums in the country. In 1979, the Currier expanded its facilities by adding two pavilions to its 1929 building. The pavilions, designed by the architectural firm of Hardy Holzman Pfeiffer, increased the museum’s exhibition space by 60%. A second major renovation and addition project was undertaken in May of 1995 and lasted through the Spring of 1996. (Currier Gallery of Art

Web Site; Grand Opening Brochure, 1996)

There were several building envelope problems to solve at this complex of art galleries. The original 1929 building

had condensation problems along the inside of the roof perimeter in the attic above the second floor galleries. The 1979 West Pavilion and Fuller Gallery pavilion wings were being renovated to house year-round

collections which require accurately controlled indoor climates. The new and existing underground art storage facilities were also receiving new climate-control systems capable of maintaining the same

conditioned environments as the galleries.

There were several building envelope problems to solve at this complex of art galleries. The original 1929 building

had condensation problems along the inside of the roof perimeter in the attic above the second floor galleries. The 1979 West Pavilion and Fuller Gallery pavilion wings were being renovated to house year-round

collections which require accurately controlled indoor climates. The new and existing underground art storage facilities were also receiving new climate-control systems capable of maintaining the same

conditioned environments as the galleries.